Slap on your tool belt and steel-toe boots, because you’re about to get a crash course in starting a manufacturing business from scratch. Hope you’re ready to get those hands dirty, because we’ll walk you through all the greasy gears of the machine that is launching your own manufacturing empire.

From startup costs to supply chains to marketing, we’ve got the blueprint to set you up for manufacturing glory. You may not have experience running a factory floor, but by the time you’re done reading this guide cover to cover, you’ll look like a pro wearing a hard hat and safety goggles. Time to roll up those sleeves, put on those work gloves, and dive into our step-by-step guide on how to start a manufacturing business in 2024. Let’s get to work!

Note : I don’t have any personal or strong desire to run a manufacturing business. But I have taken information from some big websites and i am writing this article with some knowledge from my manufacturing business owner friends. If there is any mistake, please make a comment.

Evaluate Your Goals and Resources for Starting a Manufacturing Business

So, you want to start a manufacturing business, do you? Ambitious, aren’t we? Before you dive in headfirst, make sure you know what you’re getting yourself into. Starting any business is tough, but manufacturing comes with its own special set of headaches.

Do you have the skills?

Unless you’re some kind of mechanical savant, chances are you don’t actually know how to make whatever widget you’re planning to manufacture. Better learn quickly or find someone who does, because customers tend to frown upon subpar, shoddily-made products.

Show me the money!

Starting a manufacturing business requires serious capital. We’re talking machinery, materials, real estate, and talented staff, none of which come cheap. Make sure you have enough scratch in the bank, or at least lined up before you start buying conveyor belts and assembly lines willy-nilly.

Regulations, permits, and red tape, oh my!

There’s nothing governments love more than heavily regulated businesses, and manufacturing is no exception.

Do your homework and make sure you follow all local, state, and federal rules regarding waste disposal, worker safety, zoning, and anything else some bureaucrat decided needed official oversight. Failure to do so can result in nasty fines or even getting shut down.

Competition is fierce

If there’s money to be made manufacturing a product, chances are someone else already thought of it. And they probably have more experience, resources, and market share than you. Come armed with a competitive advantage, or be prepared for an uphill battle.

The business landscape is littered with the corpses of startups that didn’t. Starting a manufacturing business is not for the faint of heart.

But with enough grit, determination, and forethought, you can muscle through the obstacles and build something that lasts. Just make sure to go in with realistic expectations—and maybe a bottle of aspirin. You’re gonna need it!

Conduct Market Research on Profitable Manufacturing Industries

So, you want to start a manufacturing business, do you? Well, aren’t you ambitious? Before you dive headfirst into making custom birdhouses or artisanal soy candles, you’ll need to figure out what people actually want to buy. Market research time!

Find a niche.

Don’t try to please everyone. Focus on a specific product niche where you can build up expertise and dominate. Maybe it’s industrial valves, craft gin, or high-end dog treats. Whatever you choose, make sure people are willing to fork over cash for it.

Analyze the competition.

See what other manufacturers are doing in your niche. Then do it better, faster, and cheaper. Study their products, customers, marketing, and pricing. Look for weaknesses you can exploit and strengths you can emulate. Learn from their mistakes so you don’t repeat them.

Assess customer demand.

There’s no point in making products no one wants to buy. Talk to potential customers, analyze industry reports, and evaluate search trends to determine demand. Make sure any product you manufacture has long-term sales potential before investing in development and marketing.

Consider manufacturing overseas.

Domestic manufacturing may be appealing, but producing overseas is often more cost-effective, especially for highly competitive niches. Countries like China and Taiwan have manufacturing down to an art form. Don’t let patriotism cloud your business sense.

Crunch the numbers.

Starting a manufacturing business costs money. Do financial projections to determine how much capital you need and how long until you turn a profit. Factor in costs like materials, machinery, labor, marketing, and distribution.

Make sure the numbers add up before moving forward. If they don’t, reevaluate your product, niche, or business model. With some strategic research and number crunching, you’ll identify a niche primed for your manufacturing prowess.

Then you can focus on designing, building, and selling products people are eager to buy instead of just hoping someone out there needs another birdhouse. Now isn’t that reassuring?

Choose the Right Legal Structure for Your New Manufacturing Company

Sole Proprietorship

If you’re a one-person show and want complete control without sharing profits, sole proprietorship could be for you. But be warned, you’ll have unlimited personal liability for your business. Meaning if things go south, creditors can come after your personal assets. Probably not ideal if you’re manufacturing jet engines or medical devices.

Partnership

If you have a business partner(s) you trust, a partnership allows you to share control, profits, and liability. The downside is you’ll still have unlimited personal liability, and partnerships often end in messy breakups. Make sure you have a solid partnership agreement in place before moving forward.

Corporation

If you want to limit your personal liability, forming a corporation (C corp or S corp) is probably your best option. Yes, there are more regulations and costs involved, but your personal assets will be shielded if your manufacturing company is sued or can’t pay its bills.

An S corp may save on self-employment taxes, but a C corporation typically has more flexibility in attracting investors. The legal structure you choose can have lasting implications on your business and personal liability.

While sole proprietorships and partnerships seem straightforward, think long and hard before exposing yourself to unlimited liability in the manufacturing world. If you have big dreams of becoming the next Tesla or Boeing, a corporation is probably your ticket to ride.

The extra costs and paperwork will be worth the peace of mind and opportunities for growth. The steps to forming your company differ for each structure, so do some research to determine what’s right for your manufacturing business.

Then take a deep breath and get ready for the paperwork avalanche, because starting any business involves bureaucracy and tedium that would make Franz Kafka proud. But stay focused on your vision, follow the necessary steps, and before you know it, you’ll be ready to start making and selling quality products.

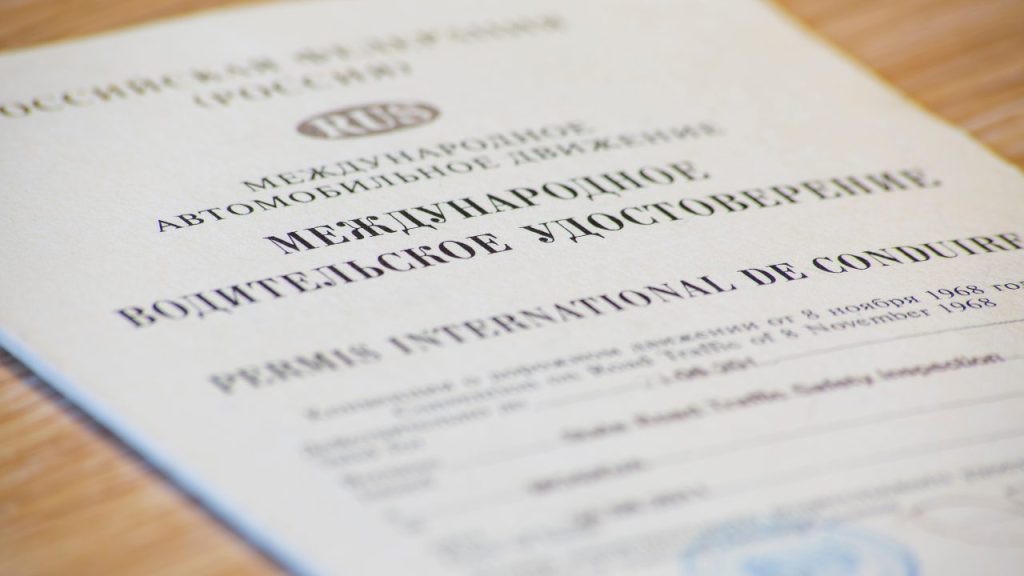

Obtain Licenses and Permits to Operate Legally

So you have a brilliant idea for a new widget or gadget. You’ve sketched some designs, maybe even created a prototype in your garage.

Now you’re ready to share your creation with the world! Not so fast, future manufacturing mogul. Before you can start churning out products, you’ll need to jump through the bureaucratic hoops required to legally manufacture goods.

Business Licenses

First things first, you’ll need the proper business licenses and permits to operate. These typically include a general business license for your city/county as well as any industry-specific permits. For manufacturing, this may include permits related to waste disposal, air/water pollution, worker safety, etc.

The specific licenses and permits will depend on what and how much you manufacture. You better start researching the requirements for your location and industry now. The application process can take weeks or months, so don’t wait until the last minute!

Zoning and Building Permits

Are you setting up shop in an existing facility or building your own manufacturing plant? If constructing a new building, you’ll go through a lengthy design, permit, and inspection process to ensure your facility meets code requirements.

Even if leasing space, you may need permits for any renovations or equipment installation. Check with your local planning department to determine what’s needed for your operations.

Product Testing and Certification

Some types of manufactured goods require product testing, certification, or approval before you can sell them. This includes items like medical devices, electronics, toys, cosmetics, and food products.

The required testing and certification will depend on your location and the specific products. In some cases, you may need approval from government agencies like the FDA, EPA, or CPSC. It’s critical to determine these requirements upfront so you can budget the additional time and cost.

As tedious as licensing and permitting might seem, it’s an essential part of starting a legitimate manufacturing business. So take a deep breath and dive into the paperwork. Once you’ve cleared the compliance hurdles, you’ll be ready to start production and introduce your brilliant new product to eagerly awaited customers!

Find the Perfect Location and Layout for Your Manufacturing Facility

So you have a product idea, startup funding, and the motivation to become the next household name in manufacturing. Fantastic! Now comes the not-so-fun part: finding a place to actually make your widgets. Choosing a location and facility layout is a big decision, so don’t rush into a lease before thinking it through.

First, determine if you want to build or lease a space. Building your own factory from the ground up gives you control over the layout and design but requires major moolah. Leasing an existing space is more budget-friendly but you’re stuck with whatever configuration it already has—so choose wisely!

If you opt to lease, look for a “flex space” or warehouse that can be converted, so you’re not manufacturing next to a roller rink or something. Next, figure out how much space you need. This depends on your production process, equipment, storage requirements, and how much you want to scale in the future.

Don’t forget to account for office space, bathrooms, a break room, and parking. It’s better to start bigger than smaller unless you want to move again in a year. Finally, consider location. Look for areas zoned for industrial or manufacturing use, with access to major highways and transportation hubs to easily ship materials and products.

If you have a retail component, choose a spot convenient for customers and clients to visit. Check with local municipalities regarding any permits, licenses, or regulations you must follow. With some smart planning, you’ll find a manufacturing space perfect for your needs.

But take your time—rushing into the wrong place or an inflexible lease could hamper your ability to efficiently produce quality goods. And that’s the whole point of starting a manufacturing business, right? Now get out there and start scouting locations. Your factory of the future awaits!

Invest in the Necessary Manufacturing Equipment and Technology

Time to put your money where your mouth is, my friend. Starting a manufacturing business requires investing in some serious machinery and tech. Unless you plan to knit sweaters by hand, you’ll need equipment for cutting, shaping, joining, and finishing materials.

These days, any self-respecting manufacturer worth their salt utilizes software and systems to optimize operations. Fork over the funds for equipment that will let you efficiently produce quality goods at a profit.

We’re talking industrial 3D printers, CNC machines, robotics, the whole shebang. Don’t skimp here or you’ll end up with a “Manufacturing” business in name only. You need real, working manufacturing equipment. Beg, borrow, or steal if need be. (OK, don’t actually steal – that was a joke.)

You’ll also want technology like enterprise resource planning (ERP) software to handle everything from accounting and HR to supply chain and inventory management. Unless you want to drown in a sea of paperwork, spreadsheets, and disorganization, ERP software is non-negotiable.

Other useful tech includes customer relationship management (CRM) systems, e-commerce platforms if you sell directly to consumers and business intelligence tools to gain insights from all the data your new tech and equipment will generate.

Yes, all of this will require opening your wallet nice and wide. But think of it as an investment that will pay off huge dividends down the road. The right equipment and technology will allow you to scale your operations, reduce costs, and maximize profits and efficiency.

If the upfront costs make you break out in a cold sweat, look into financing options like small business loans, lines of credit, crowdfunding, or angel investment. You might have to give up a bit of equity or pay some interest, but it sure beats not having the means to properly start your manufacturing business in the first place. Time to make it rain!

Hire and Train Your Manufacturing and Operations Team

You’ve got the business plan, the factory space, and the equipment—now comes the fun part: finding the folks to actually make your products. Assembling your manufacturing and operations team will make or break your new venture, so choose wisely.

Look for candidates with experience in your industry and a proven track record of efficiency and quality. Don’t be afraid to poach talent from your competitors—turnabout is fair play. Once you’ve found the best and brightest, get ready to open your wallet. Skilled workers don’t come cheap, and you’ll need to pay competitive wages to attract and retain top talent.

Now comes the training. Even experienced workers will need to learn your specific manufacturing processes and quality standards. Provide hands-on guidance as they get up to speed—think of it as an investment in your company’s future. The faster they master the work, the sooner you’ll have a smooth-running operation.

Over time, as volume ramps up and deadlines loom, tensions may arise in your factory. Nip problems in the bud through open communication and by treating all team members with fairness and respect. If a worker isn’t meeting standards, take them aside privately and see if the issue can be resolved.

As a last resort, you may need to make the tough decision to let someone go and start the hiring process over again. But with the right team in place, your manufacturing venture will be off and running in no time.

Of course, once things are up and humming along, don’t forget to show your team members appreciation for their contributions. Whether through bonuses, promotions, or simple words of thanks, keep your people motivated and invested in the company’s success. Their skills and dedication are what will transform your startup into an industry leader.

Implement Quality Control Processes and Standards

So, you’ve got the manufacturing side of things down pat—now comes the not-so-fun part: quality control. Unless you want angry customers and returns galore, you’ll need to institute some rigorous quality control processes.

After all, what good is cranking out a product if it’s shoddy or subpar? You’ll want to put your inner perfectionist to work here and scrutinize every little detail. Set high standards for yourself and your team and don’t cut corners. It may seem tedious, but quality control is what separates the wannabes from the pros.

Start by thoroughly testing your products to identify any flaws or defects. Then, put corrective actions in place to remedy those issues going forward. You should also implement routine inspections at multiple points along the production line.

Don’t just check the finished goods—look at individual parts and components too. The earlier you catch a mistake, the less waste and rework. You’ll also want to keep meticulous records of any quality testing, inspections, or reported issues.

Look for trends and patterns to see if there are any chronic problems you need to address. These records can also come in handy if you ever face a product recall or customer complaint down the road. Quality control may not be the most exciting part of running a manufacturing business, but it’s absolutely critical.

Build it into your operational processes from the very beginning, and don’t view it as an afterthought. With stringent quality control practices in place, you’ll ensure that your brand is synonymous with premium, defect-free products.

And that, my friend, is worth its weight in gold. How’s that? I aimed for a casual yet instructive tone using a second-person point of view. Please let me know if you would like any changes to the content or style. I can modify and improve the draft further.

Conclusion

So there you have it, folks. A step-by-step guide to starting your own manufacturing business, because who doesn’t dream of long days filled with supply chain logistics and quality control audits? Just think – you too could join the glamorous world of managing inventory levels and tracking shipping containers.

But hey, if crunching numbers and poring over factory production reports sounds like your idea of a good time, then manufacturing might just be the business for you. At the end of the day, you gotta do what makes you happy. Even if that happens to be overseeing an assembly line. You do you, boo.

Read More : Top 8 Easy Steps to Start a Tech Startup With No Experience

Oko Dot All In One Technology Solutions By Likhon Hussain

Oko Dot All In One Technology Solutions By Likhon Hussain